How Durable and Corrosion-resistant is Aluminum Extrusion and How Should It Be Maintained?

What is aluminum extrusion?

Aluminum extrusion profiles refer to the specific shapes and designs of aluminum extrusions. Aluminum extrusion is a process for creating parts with specific cross-sectional profiles by pushing heated alloy material through a die. Their profiles can vary widely depending on the requirements of the application and the design of the die used during the extrusion process. They have various shapes such as T-shapes, I-shapes, L-shapes, square shapes, round shapes or custom-designed profiles with complex geometries. They can accommodate additional components or facilitate assembly with slots, grooves or other features. Therefore, they are widely used in industries such as construction, transportation, electronics and many others.

How durable and corrosion-resistant is aluminum profile?

Aluminium extrusion profiles are known for their durability and corrosion resistance. They are durable and have excellent corrosion resistance because aluminum spontaneously forms a thin but effective oxide layer that prevents further oxidation. This is why aluminum is such a quality, durable metal. And aluminium oxide is impermeable and it sticks very strongly to the parent metal. If the layer is damaged mechanically, the oxide layer of aluminum will repair itself immediately, returning to its protective form. Also, since aluminum contains no iron, it cannot rust.

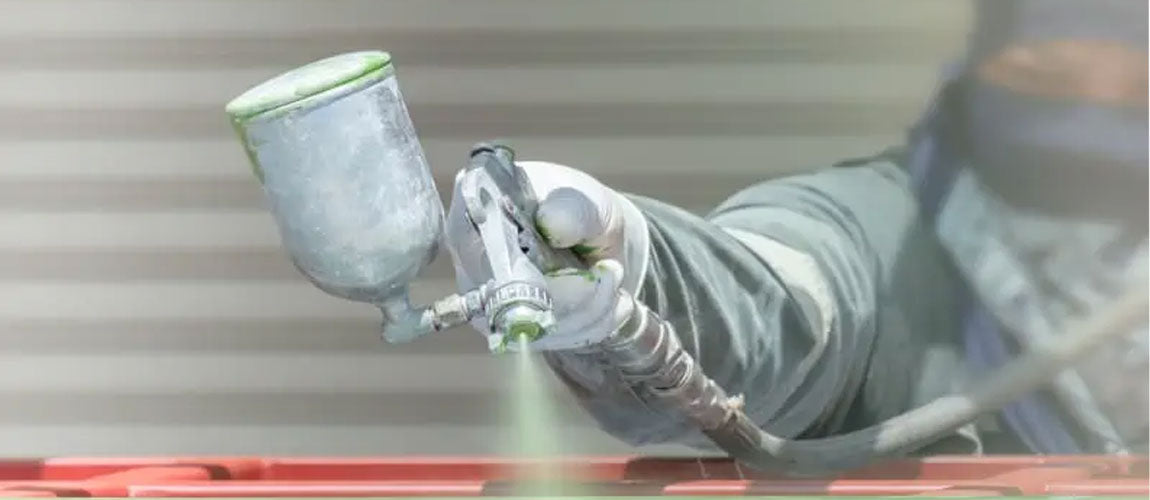

Additionally, aluminum extrusion profiles can be further treated or coated to enhance their corrosion resistance. Surface finishing can enhance appearance and corrosion protection.

For example, the process of anodization thickens the aluminum extrusion’s naturally-occurring oxide layer, improving its corrosion resistance and also making the aluminum extrusion more resistant to wear. In addition, other finishing processes such as painting, powder coating, sandblasting and sublimation (to create a wood look), can be undergone for the aluminum extrusion as well.

Overall, aluminum extrusion is known for its excellent durability and corrosion resistance, making it a popular choice for a wide range of industries and applications.

Where to buy aluminum extrusion?

1. Local Hardware Stores: Many local hardware stores or home improvement centers carry a variety of aluminum extrusions in different shapes and sizes. These stores often have a dedicated section for metal supplies where you can find aluminum extrusions.

2. Online Retailers: There are numerous online retailers that specialize in selling aluminum extrusions. Some popular options include Amazon, eBay, and specialized metal suppliers' websites. These platforms offer a wide range of options, and you can easily compare prices and specifications.

3. Manufacturer Direct: In some cases, you may be able to purchase aluminum extrusions directly from the manufacturers themselves. This option can provide you with a broader range of options and potentially better prices. Contact aluminum extrusion manufacturers or visit their websites to inquire about purchasing options.Bella Bays is 100% manufacturer direct for aluminum extrusions, here is the link: https://bellabays.com/

How to maintain the aluminum extrusion?

Here are some guidelines for reference.

Regular inspecting

Regularly inspect the aluminum extrusion profile for any signs of damage such as dents, scratches or cracks. To prevent further deterioration or compromise in structural integrity, you should solve any issues promptly.

Regular Cleaning

Regularly clean the aluminum extrusion to remove dirt, dust, and other contaminants. Clean the aluminum extrusion by using a mild detergent or a non-abrasive cleaner with a soft cloth or sponge. Note, the harsh chemicals or abrasive materials can scratch or damage the surface of aluminum extrusion profiles. Please don’t use them.

No corrosive substances

Aluminum extrusion is susceptible to corrosion with the corrosive substances such as saltwater, acids or alkaline solutions, especially in harsh environments. Please use clean water to rinse the aluminum extrusion promptly and dry it thoroughly when contact occurs.

Avoid excessive heat

Aluminum extrusion can cause deformation or even melting in direct contact with flames or high-temperature equipment. Please avoid exposing the aluminum extrusion to excessive heat sources because aluminum has a relatively low melting point.

In addition, due to reduce friction & wear and ensure smooth operation, it is a good choice to apply a suitable lubricant to moving parts or joints of the aluminum extrusion. The moving parts or joints include hinges or sliding mechanisms. Some lubricants are specifically designed for aluminum and please use them.

In a word, you can ensure the longevity and optimal performance of your aluminum extrusion by following the above maintenance practices.

Leave a comment